Linear Measurement, Introduction to measurement, Vernier calipers, Digital caliper, Micrometers, Outside micrometer, Inside micrometer, Screw thread, Depth micrometer, Vernier micrometer,Vernier height gauge, Vernier depth gauge, Comparators, Screw pitch gauge, Wire gauge, Plate gauge, Radius gauge, Fillet gauge, Template gauge, Feeler gauge, Slip gauge or Gauge blocks

Introduction to measurement

Measurement systems are mainly used in industries for

quality control management. Often quality control engineers are applying some

of the measuring systems such as linear -and angular measurements. These

measurements are very much useful to compare the actual measurements with

already existing standard measurements. In practice, we come across many

parameters to be measured in a given situation. For example, in a pneumatic

drilling, we have to measure the pressure at which air is, the speed at which

the drill operates, the depth through which drilling has been done and so on.

Linear measuring instruments:

The linear measurement includes the measurement of lengths,

diameters, heights and thickness. The basic principle of linear measurement is

that of comparison with standard dimensions on a suitably engraved instrument

or device. The various devices used for measuring the linear measurements are;

• Vernier calipers

• Micrometers

• Slip gauge or gauge blocks

• Comparators.

The Vernier principle:

The basic principle of the Vernier is that the smallest unit

of size to which a Vernier can be read is equal to the difference in the length

between the divisions of the two scales. The magnification on the Vernier scale

is given by two scales sliding over each other. The eye can detect which

divisions on one of them are smaller than those on the other. It is the fact

which enables us to read a Vernier to 0.02 mm accuracy.

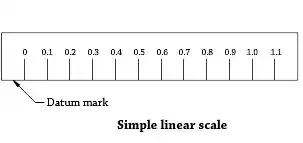

Figures show the vernier principle being used to determine

the reading. Figure shows the main scale with the datum line marked.

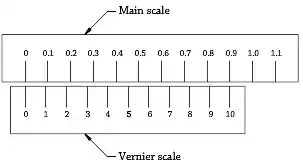

Figure shows the main scale and Vernier scale with

graduations. The Value of 1 main scale is 0.1 unit. In Vernier scale 9 such

units are taken and divided into 10 equal parts. Hence the Value of 1 Vernier

scale is, 0.9/10 = 0.09 units

Now, by applying the Vernier principle, the smallest unit of

size is 1 M.S.D. — 1 V.S.D. [i.e.] 0.1 -0.09 = 0.01 unit.

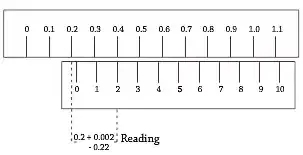

Definition of the least count:

The least count is the smallest possible measurement that

can be taken with the precision instrument. The zero of the Vernier scale is

between 0.2 to 0.3 units on the main scale and number 2 graduation of the

Vernier scale is coinciding with the 4th division of the main scale.

Measurement of reading:

Example 1

0.3 mm

0.3 mm

'0' of vernier is to the right of '0' of the main scale and

lies between '0' and 1st division of the main scale. The 3rd division of the

vernier scale coincides with a division on the main scale. Hence measurement is

0 mm + 3 X 0.1 mm = 0.3 mm.

Example 2

44.4 mm

44.4 mm

'0' of the vernier scale lies between the 44th and 45th

divisions of the main scale and the 4th division of the vernier scale coincides

with a division of the main scale.

Hence the measurement is 44 mm + 4 x 0.1 mm = 44.4 mm.

'0' of the vernier scale lies between the 53th and 54th

divisions on the main scale and the 8th division of the vernier scale coincides

with a division on the main scale.

Hence measurement is 53 mm + 8 x 0.1 mm = 53.8 mm

Vernier caliper and its application:

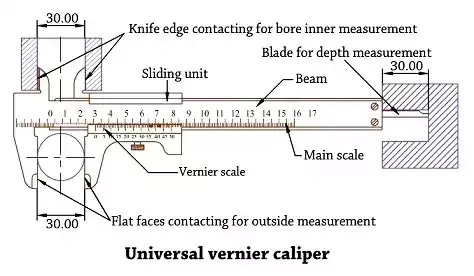

One of the precision instruments having the principle of

Vernier applied to it is the universal vernier caliper. The universal vernier

caliper is mainly used,

• To take outside measurement.

• To take inside measurement.

• To take depth measurement.

A universal Vernier caliper consists of a;

• Beam

• Fixed jaw for external measurements

• Sliding unit consisting of

» Movable jaw for external measurements

» Movable jaw for internal

measurements

» Blade for depth

measurement

• Main scale

• Vernier scale

• Fine adjustment screw

• Set of locking screws

All parts are made up of nickel-chromium steel, heat

treated. They are machined to high accuracy. They are stabilized to avoid distortion

due to temperature variations.

Constructional features:

The beam is the main part and the main scale graduations are

marked on it. The markings are in millimeters and every tenth line is drawn a

little longer and brighter than the other graduations and numbered as 1,2,3 ...

To the left of the beam the fixed jaws for external and internal measurements

are fixed as integral parts. The vernier unit slides over the beam. At the

bottom face of the beam a keyway-like groove is machined for its full length,

permitting the blade to slide in the groove. At the bottom right hand end, a

unit is fixed serving as a support for the blade ‘ when it slides in the

groove. The Vernier unit has got the Vernier graduations marked on it. The

movable jaws for both external and internal measurements are integral with

this. The fixed and movable jaws are knife-edged to have better accuracy during

measurement. When the fixed and movable jaws are made to contact each other,

the zero of the Vernier scale coincides with the zero of the main scale. At this position the blade will be in line with the right

hand edge of the beam. When the Vernier scale unit slides over the beam, the

movable jaws of both the measurements as well as the blade advance to make the

reading. To slide the Vernier unit, the thumb lever is pressed and pulled or

pushed according to the direction of movement of the Vernier unit.

The application of the universal Vernier caliper in taking

external, internal and depth measurements is shown in figure.

Advantage:

• No need to have separate precision instruments for taking

external, internal and depth measurements.

Disadvantages:

• Accuracy of reading depends on the skill of the operator.

• Losses its accuracy by constant usage as slackness in the

sliding unit develops.

• Cannot be used to measure components having deviations

less than +/-0.02 mm.

Digital caliper:

The digital caliper [sometime incorrectly called the digital

Vernier caliper] is a precision instrument than can be used to measure internal

and external distance accurately to 0.01 mm. The digital Vernier caliper is

shown in below figure.

The distance or the measurements are read from LED drawing.

The parts of digital calipers are similar to the ordinary vernier caliper except

the digital display and few other parts. Earlier versions of the type of

measuring instrument had to read by looking carefully at the inch or metric

scale and there was a need for very good eye sight in order to read the small

sliding scale. Manually operated Vernier caliper are remain popular because

they are much cheaper than the digital version. The digital caliper requires a

small battery whereas the manual version does not need any power source. The

digital calipers are easier to use as the measurement is clearly displayed and

also, by pressing inch/mm button the distance can be read as metric or inch.

The display is turned on with the ON/OFF button. Before measuring, the zero

setting to be done, by bringing the external jaws together until they touch

each other and then press the zero button. Now the digital caliper is ready to use. Always set zero position when turning on the display for the first time.

Graduations and reading of Vernier caliper

Vernier caliper:

The Vernier principle states that two different scales are

constructed on a single known length of line and the difference between them is

taken for fine measurements.

Least count of Vernier caliper:

The main scale divisions 9 mm are divided into 10 equal

parts in the Vernier scale

• One main scale division [MSD] = 1mm,

• Least count = 1 MSD - 1 VSD

= 1 mm - 9/10 = 0.1 mm

• The difference between one MSD and one VSD = 0.1 mm

Vernier Measurements:

The Vernier calipers are available with different

graduations and least counts. Reading measurements with a Vernier caliper, the

least count should be determined first.

The graduations of a common type of Vernier caliper with a

least count of 0.02 mm. In this, 50 divisions of the Vernier scale occupy 49

divisions [49 mm] on the main scale.

Example:

Main scale reading = 60 mm

The Vernier division coinciding with the main scale is the

28th division, value = 28 X 0.02 = 0.56 mm

Reading = 60 + 0.56 = 60.56 mm.

Micrometer

Micrometer:

It is a precision tool used to measure up to an accuracy of

0.01 mm. Various micrometers are,

• Outside micrometer

• Inside micrometer

• Screw thread

• Depth micrometer

• Vernier micrometer

Accuracy of calipers:

The accuracy of the measurement with calipers depends very

much on;

• The sense of touch while measuring the component.

• The accuracy of calipers used with steel rules is limited

to 0.5 mm.

Outside micrometer:

• The purpose of a metric micrometer is to read an accuracy

of 0.01 mm of an object

• It is available in various sizes.

• The principal parts of a micrometer are the frame, anvil,

spindle and the thread, sleeve or barrel and the thimble.

• There is a knurled collar or small lever on the frame to

lock the spindle in the barrel.

• In addition to this, a ratchet stop is provided to the

spindle in order to prevent a possible excess pressure on the screw treads.

• The sleeve or barrel is marked with the main scale in

full mm and half mm.

• The thimble bevel end is graduated with the thimble

scale.

• Fifty equal divisions are made on the circumference of

the thimble bevel end.

• Every 5"‘ division of the graduation is indicated

with the number.

• The spindle face is fitted with a carbide tip to resist

the wear.

• The spindle with the screw is attached to the thimble of

the micrometer.

• The corresponding threaded nut is fitted to the barrel or

sleeve of the micrometer.

• The other measuring face of the micrometer is the anvil,

which is normally fitted i with a carbide tip to resist the wear.

• The range of micrometers are 0 - 25 mm, 25 - 50 mm, 50 - 75,

75 - 100 mm etc.

• The spindle can be easily screwed down in the barrel.

• When the face of the anvil and the face of the spindle

are in contact, the 0 graduations of the index line and 0 graduation of the

thimble coincide with each other.

• The spindle may be withdrawn by rotating the thimble in

an anticlockwise direction.

• The thimble portion is knurled to provide a good grip for

holding as well as for rotating the spindle.

Inside micrometer:

• The inside micrometer is similar to an ordinary outside

micrometer but without the’ U‘ frame.

• The measurement is taken over the contact points. As the

thimble opens or closes, the contact points get opened or closed.

• The inside micrometer consists of a sleeve, thimble,

anvils, a spacing collar and extension rods.

• It is also equipped with a handle to measure deep bores.

• The least count of the instrument is also 0.01 mm.

• The inside micrometer is equipped with a 12 mm spacing

collar and 4 extension rods for measuring holes of ranges 50-75 mm, 75-100 mm,

100-125 mm and 125- 150 mm.

• The sleeve is marked with the main scale and the thimble

with the thimble scale.

• When the inside micrometer is closed [when zero of

thimble coincides with the zero of the barrel].

• It is capable of reading the minimum dimension of 25 mm.

• In addition to this, it is possible to read up to 38 mm

with the thimble opening to the extreme right.

• In order to read further higher ranges, a standard

spacing collar of 12 mm width is to be added.

• This facilitates the micrometer to read a maximum range

of 50 mm.

• Similarly, each extension rod has to be used without the

collar for measuring a minimum range up to 13 mm variation and with the collar

for a maximum range of measurements.

• A clamping screw is also provided to clamp the extension

rod firmly.

Depth micrometer:

• It is used to measure the precise depths of holes,

grooves and recesses by using interchangeable rods to accommodate different

depth measurements.

• When using a depth micrometer, you must make sure the

base of the micrometer has a flat, smooth surface to rest on and that it is

held firmly in place to ensure an accurate measurement.

• A set of extension rods is generally supplied.

• The range of sizes that can be measured with rod is

engraved as 0 - 25, 25 - 50, 50 - 75,75 - 100,100 - 125 and 125 - 150 mm.

• The extension rods can be inserted inside the thimble and

the sleeve.

• The extension rods have a collar head which helps the rod

to be held firmly.

• The measuring faces of the stock and the rods are

hardened, tempered and ground.

• The measuring face of the stock is machined perfectly

flat.

• The extension rods may be removed and replaced according

to the size of depth to be measured.

Screw thread micrometer:

• Is used to measure the pitch diameter of screw with

accuracy of 0.01 mm.

• It looks similar to outside micrometer.

• The screw thread micrometer has a 60-degree pointed

spindle and a double V-shaped swivelling anvil.

Vernier micrometer:

• Vernier micrometer is used to measure up to an accuracy

of 0.0001 inch.

• In addition to the thimble and sleeve graduations, it has

a vernier scale on the sleeve.

• The Vernier scale has 10 equal divisions running parallel

above the barrel mark in a space of 9 divisions of thimble.

• Each division of Vernier scale represents (0.009/10] =

0.0009 inch.

• The difference between one thimbie division and Vernier

scale division is [0.001 -0.0009] = 0.0001 inch.

• Reading on sleeve = 9 x 0.025 = 0.2250 inch

• Reading on thimble = 11 x 0.001 = 0.011 inch

• Reading on Vernier scale = 3 x 0.0001 = 0.0003 inch

• Size = 0.2363 inch

Depth & Height Gauges

Vernier height gauge:

A height gauge is a measuring device used either for

determining the height of work-piece.

These measuring tools are used in metal working to either set or measure vertical distances, the pointer is sharpened to allow it to act as a scriber and assist in marking out work pieces.

These measuring tools are used in metal working to either set or measure vertical distances, the pointer is sharpened to allow it to act as a scriber and assist in marking out work pieces.

Usage of Vernier height gauge:

• Accurate measurements are important in layout and

inspection work.

• Vernier height gauges are particularly suitable for

marking off accurate distances, and centre locations.

• The graduations and readings are the same as those of a

Vernier caliper.

Important parts of Vernier height gauge:

The main parts of a Vernier height gauge and their functions

are,

• Base:

It is the datum from which measurements and settings are

made. The underside of the base is hardened, ground and lapped.

• Beam:

It is similar to the beam scale of a vernier caliper and is

attached t0 the base.

• Vernier Slide:

This unit slides on the beam and carries the vernier plate,

locking screws, fine setting device and scriber. Vernier height gauges of some

are provided with a rack and pinion arrangement for moving the slide along the

beam. Vernier height gauges are provided with both straight and offset

scribers.

Zero setting of the Vernier height gauge:

• The offset scriber permits zero setting of the instrument

from the datum surface.

• While using a straight scriber, the zero setting of the

instrument is at a level above the datum surface.

• The zero setting is to be checked using the precision

round block, supplied along with the instrument.

• Vernier height gauges with which we can measure from the

datum surface without the special offset scribers are also available.

• The size of the vernier height gauge is stated by the

height of the beam.

• The most commonly used size has a beam of 300 mm height.

• Vernier height gauges are used with surface plates or

other accurate flat surfaces.

Vernier depth gauge:

• Works on the same principle of Vernier caliper.

• Designed for measuring the depth of blind holes and

slots.

• By using this instrument, the base is held firmly against

the reference surface.

• The blade is lowered into the hole until the blade

touches the surface of the hole.

• After tightening, the clamping screw is moved from the

hole and read in the same way as the vernier caliper.

Application of vernier depth gauge:

• A vernier depth gauge is a very commonly used precision

instrument for the measuring of holes, recesses, slots and steps.

• Its construction and method of reading are similar to

those of a Vernier caliper.

Parts of a vernier depth gauge:

• Base [1], Graduated beam [2], Clamping screw [3], Fine

adjustment mechanism [4] and Vernier scale [5].

• The base [Anvil] is the fixed unit and serves as a datum

for measurement.

• It also carries the Vernier scale and the fine adjustment

mechanism.

• The beam with the main scale graduations is the sliding

member or part.

• Fine adjustments for measurement are made after

tightening the clamping screw and the fine adjustment mechanism.

• The relief given at the end of the beam of some vernier

depth gauges is to avoid the seating in the corners of slots and to ensure

correct reading.

• Remove burrs, if any, before taking measurements.

• Excessive pressure on the beam, while taking measurements

will lift the base from the reference surface and will show wrong measurements.

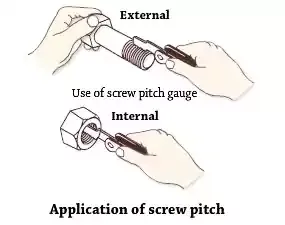

Screw pitch gauge:

A screw pitch gauge is used to determine the pitch of a

thread. It is also used to compare the profile of threads.

Constructional features:

• Pitch gauges are available with a number of blades

assembled as a set.

• Each blade is meant for checking a particular standard

thread pitch.

• The blades are made of thin spring steel sheets, and are

hardened.

• Some screw pitch gauge sets will have blades provided for

checking British standard thread [BSW, BSF etc.) at one end and the metric

standard at the other end.

• The thread profile on each blade is cut for about 25 mm

to 30 mm

• The pitch of the blade is stamped on each blade.

• For obtaining accurate checking while using the screw

pitch gauge, the full length of the blade should be placed on the threads.

Wire gauge:

• It consist of oblong plate having holes of different size

to receive different size wires.

• Each hole is stamped with a number which define the holes

and wire size.

• This stamped number starts from 1 to 80.

• This wire gauge also available in circular shape.

Plate gauge:

• Sheets are sold as flat, rectangular sheets of standard

size.

• It is specified using standard gauge numbers usually from

16 gauge down to 30 gauge.

• Sheet metal gauges refer to the thickness of a particular

type of sheet metal product.

• Larger the gauge number, lesser will be the thickness.

• Gauge is a single number measurement of the thickness of

the sheet.

• The equivalent thickness differs for each gauge size

standard, which were developed based on the weight of the sheet for a given

material.

• Micrometer and thickness measuring gauge is used to

measure sheet metal thickness.

• Standard gauge is used to check and separate coils.

Radius and fillet gauges:

• Components are machined to have curved formation on the

edges or at the junction of two steps. They are called radius and fillets.

• The size of the radius and fillet is normally provided on

a drawing.

• The gauges used to check the radius formed on the edges of

diameters are fillet gauges.

• The gauges used to check the fillets are called radius

gauges.

• They are made of hardened sheet metal each to a precise

radius.

• They are used to check the radii by comparing the radius

on a part with the radius of the gauge.

The other typical applications are:

• The radius and fillet gauges are available in sets of

several blades which fold into a holder when not in use.

• Each blade can be swung out of the holder separately, and

has its size engraved on it.

Template gauge:

• Template gauges consist of a set of steel or plastic pins

that are set tightly against one another in a frame which keeps them in the

same plane and parallel while allowing them to move independently,

perpendicularly to the frame.

• When pressed against an object, the pins conform to the

object.

• The gauge can then be used to draw the profile or to copy

it on to another surface.

Feeler gauge:

• These are thin steel blades hardened and ground to

various sizes.

• They consist of a number of small lengths of steel of

different thicknesses with measurements marked on each piece.

• Used for checking the clearance between two mating parts.

• Vanes are from 0.03 to 1 mm thickness.

Gauge block:

• Slip gauges are gauge blocks used as standards for

precision length measurement.

• It is used as a reference for the calibration of

measuring equipment used in machine shops, such as micrometers, sine bars,

calipers, and dial indicators.

• Gauge blocks come in sets of blocks of standard lengths.

• In use, the blocks are stacked end-to-end to make up the

desired length.

• Gauge blocks are the main means of length standardization

used by industry.

• These slip gauges are available in various sets with

different numbers.

• A particular size can be built-up by wringing individual

slip gauges together.

• Wringing is the act of joining the slip gauges together while building up to sizes.

• Wringing is the act of joining the slip gauges together while building up to sizes.

Selection and Determination of Slip Gauges for Different Sizes:

Uses of slip gauge:

Slip gauges are used,

• For precise measurement of parts.

• For verifying measuring tools such as,

(i) Micrometers

(ii) Comparators

(iii) Various limit gauges.

END

0 Comments