DESIGN PROCEDURE OF KNUCKLE JOINT

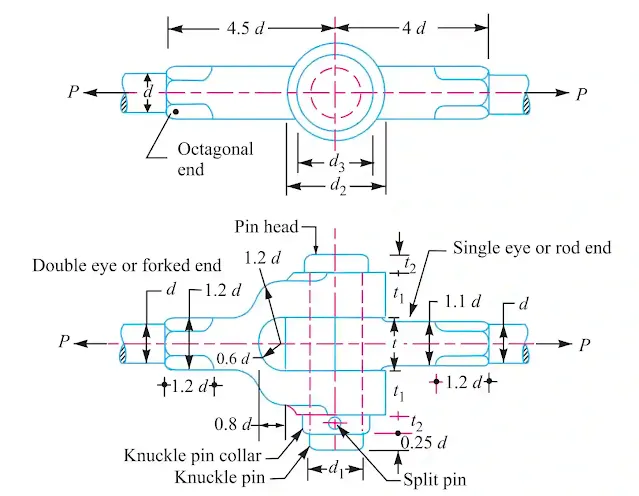

The dimensions of various parts of the knuckle joint are fixed by empirical relations as given below. It may be noted that all the parts should be made of the same material i.e. mild steel or wrought iron.

If d is the diameter of rod, then diameter of pin, d1 = d

Outer diameter of eye, d2 = 2 d

Diameter of knuckle pin head and collar, d3 = 1.5 d

Thickness of single eye or rod end, t = 1.25 d

Thickness of fork, t 1 = 0.75 d

Thickness of pin head, t2 = 0.5 d

P = Tensile load acting on the rod

σt , τ and σc = Permissible stresses for the joint material in tension, shear and crushing respectively.

Other dimensions of the joint are shown.

WATCH THIS VIDEO FOR DESIGN PROCEDURE OF KNUCKLE JOINT

Example 1. Design a knuckle joint to transmit 150 kN. The design stresses may be taken as 75 MPa in tension, 60 MPa in shear and 150 MPa in compression.

Solution:

WATCH THIS VIDEO FOR SOLUTION

Example 2. Design a knuckle joint for a tie rod of a circular section to sustain a maximum pull of 70 kN. The ultimate strength of the material of the rod against tearing is 420 MPa. The ultimate tensile and shearing strength of the pin material are 510 MPa and 396 MPa respectively. Determine the tie rod section and pin section. Take factor of safety = 6.

Solution:

WATCH THIS VIDEO FOR SOLUTION

END

0 Comments