Grinding Machine, Purpose of grinding, Advantages of grinding, Disadvantages of grinding, Applications of grinding, Types of grinding, Surface grinding methods, Classification of grinding machines, Grinding wheel, Abrasives, Bond and bond materials, Grits, Grade, Structure, Selection of grinding wheels, Maintenance of grinding wheel

Introduction to grinding:

• Grinding

is metal cutting operation performed by means of a rotating abrasive wheel that

acts as a tool.

• This is

used to finish workpieces which must show a high surface quality, accuracy of

shape and dimension.

• The art of

grinding goes back many centuries. Over 5,000 years ago, the egyptains abraded

and polished building stones to hairline fits for the pyramids, columns and

statues were shaped and finished with a globular stone which abraded the

surface.

• Mostly

grinding is the finishing operation because it removes comparatively little

metal, 0.25 to 0.50mm in most operations and the accuracy in dimensions is in

the order of 0.000025 mm.

• Grinding

is also done to machine materials which are too hard for other machining

methods that use cutting tools.

• Many

different types of grinding machines have now been developed for handling

various kinds of work to which the grinding process is applicable.

Purpose of grinding:

• To bring

the component to close size.

• To obtain

required surface finish.

• To machine

very hard surfaces.

Advantages of grinding:

• The

surface finish obtained is superior.

• One of the

most dimensionally accurate machining processes.

• Hardened

components can be machined.

• Grinding

permits to machine light and delicate parts due to requiring little pressure.

• Surface

unevenness can be eliminated.

• Various

kinds of works can be grinded.

• Designed

geometrical configuration can be achieved.

• It removes

little material of order 0.25 to 0.50mm.

Disadvantages of grinding:

• Work

surface gets over heated.

• Wheel wear

results duplicate parts do not have the same dimensions.

• Grinding

is not suitable for heavy metal removing.

• For some

complicated parts grinding needs attention.

• Achieving

true parallelism requires skill.

• Achieving

concentricity needs attention.

• Achieving

true parallelism requires skill.

• Achieving

concentricity needs attention.

Applications of grinding:

• All cast

components require grinding.

• Welded

components require grinding.

• Crank

cases, forged components.

Types of grinding:

Grinding

operation can be classified into two different categories:

(i) On the

basis of quality of grinding;

• Rough

grinding or non precision grinding.

• Precision

grinding.

(ii) On the

basis of surface to be ground;

• External

grinding

• Internal

grinding

• Surface

grinding

• Form

grinding.

Rough grinding:

• The rough

grinding are snagging and off hand grinding where the work is held in the

operators hand.

• The work

piece is pressed against the wheel.

• Rough

grinding used where, the accuracy and surface finish are secondary factor.

• Some of

the application of rough grinding are, trimming the surface left by sprues and

risers on casting, grinding part line on casting, removing flash on forgings,

excess metal on welding etc.

Precision grinding:

• Precision

grinding concerned with producing good surface finishing and high degree of

accuracy.

• The wheel

or work both are guided in precision paths.

• Precision

grinding is followed after rough grinding.

Surface grinding methods

External cylindrical grinding:

• External

cylindrical grinding produces a straight or tapered surface on a workpiece,

shown on figure below.

• Workpiece

must be rotated about its own axis between centres as it passes lengthwise

across the face of a revolving grinding wheel.

Internal cylindrical grinding:

• Internal

cylindrical grinding produces internal cylindrical holes and tapers, shown in

figure below.

• The

workpieces are chucked and precisely rotated about their own axis.

• The

grinding wheel rotates against the sense of rotation of the workpiece.

Surface grinding:

• Surface

grinding produces flat surface.

• The work

may be ground by either the periphery or by the end face of the grinding wheel.

• The

workpiece is reciprocated at a constant speed below or on the end face of the

grinding wheel.

Form grinding:

• Form

grinding is done with specially shaped grinding wheel.

• That grind

the formed surfaces as in grinding gear teeth, threads, splined shafts, holes,

etc.

Centreless grinding:

• In this

process, the work is supported between grinding wheel and regulating wheel on

work rest blade.

• The

principle of centreless grinding is shown in figure.

• Used when

long slender bars are to be finished.

Classification of grinding machines

The grinding

machine can be classified as;

•

Cylindrical grinding machine

(i) External

cylindrical grinder

(a) Centre

type

(b)

Centreless type

(ii)

Internal cylindrical grinder

(a) Centre

type

(b)

Centreless type

• Surface

grinding machines

(i) Vertical

spindle

(a)

Reciprocating table

(b) Rotary

table

(ii)

Horizontal spindle

(a)

Reciprocating table

(b) Rotary

table

• Tool and

cutter grinding machines

• Special

grinding machines.

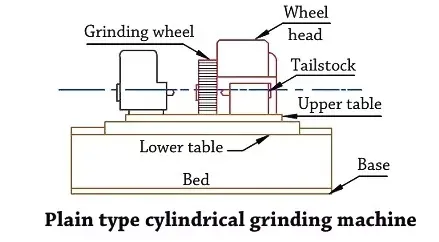

Cylindrical grinding machine:

A

cylindrical grinding machine is similar to the lathe, but on which a grinding

wheel is mounted instead of the single point cutting tool.

Plain

milling cutters are divided into;

• Base

• Table

• Headstock

• Tailstock

• Cross

feed, and

• Wheel

head.

Base:

• The base

or bed is the main casting that rests on the floor and supports the parts

mounted on it.

• On the top

of the base are precision horizontal ways set at right angles for the table to

slide on.

• The base

also houses the table-drive mechanism.

Table:

• There are

two tables-lower table and upper table.

• The lower

table slides on ways on the bed provides traverse of the work past the grinding

wheel.

• It can be

moved by hand or power within desired limits.

• The upper

table that is pivoted at its center is mounted on the top of the sliding table.

• It has

T-slots for securing the headstock and tailstock and can be positioned along

the table to suit the length of the work.

• The upper

table can he swivelled and clamped in position to provide adjustment for

grinding straight or tapered work as desired.

• Setting

for tapers upto ±100 can be made in this way.

• Steep

tapers are ground by swivelling the wheel head.

• Adjustable

dogs are clamped in longitudinal slots and they are provided at the side of the

lower or sliding table and set up to reverse the table at the ends of the

stroke.

Headstock:

• The

headstock supports the workpiece by means of a dead center and drives it by

means of a dog, or it may hold and drive the workpiece in a chuck.

Tailstock:

• The

tailstock can be adjusted and clamped in various positions to accommodate

different lengths of workpieces.

Wheel head:

• The wheel

head carries a grinding wheel and its driving motor is mounted on a slide at

the top and rear of the base.

• The wheel

head may he moved perpendicularly to the table ways, by hand or power, to feed

the wheel to the work.

Cross feed:

• The

grinding wheel is fed to the work by hand or power as determined by the

engagement of the cross-feed control lever.

• On

cylindrical grinding machines, the operation may he stopped automatically when

the workpiece has been finished to size.

• In one

method it uses an automatic caliper type gauging attachment to measure the

workpiece and stop the operation at the proper time.

Working of cylindrical grinding machine:

• The workpiece

is usually held between dead centers and rotated by a dog and driver on the

face plate as shown in figure.

• The work

may also be rotated about its own axis in a chuck.

• There are

four movements involved in a cylindrical centre-type grinding,

(i) The work

must revolve

(ii) The

wheel must revolve

(iii) The work

must pass the wheel

(iv) The

wheel must pass the work.

• They are

equipped with a mechanism which enables the grinding wheel to be fed in

automatically towards the work for successive cuts.

• Hand feed

is employed only in adjusting the wheel or starting the cut.

• A

provision is also made for varying the longitudinal movement of the work or the

wheel.

• Hydraulic

rather than mechanical controls are preferred on grinding machines to cause

minimum vibration.

• Figure

illustrates schematically this machine,

• The

machine is similar to a centre lathe in many respects.

• A disc

type grinding wheel performs the grinding action using the peripheral surface.

• Both

traverse and plunge grinding can be carried out in this machine.

Traverse grinding:

• The work

is reciprocated as the wheel feeds to produce cylinders longer than the width

of the wheel face.

Plunge grinding:

• The work

rotates in affixed position as the wheel feeds in to produce cylinders of a

length equal to the width of the wheel.

• The

important advantage is that cylindrical shapes can be produced as easily as

straight cylinders in a single "plunge" of the wheel simply by

forming the periphery of the wheel.

Surface grinding machines:

• Surface

grinding machines are generally used for grinding flat surfaces. These machines

are similar to milling machine in construction as well as in motion.

• Some types

of surface grinders are also capable of producing contour surface with formed

grinding wheel.

• Basically

there are four different types of surface grinding machines characterized by

the movement of their tables and the orientation of grinding wheel spindles as

follows,

(i)

Horizontal spindle and reciprocating table

(ii)

Vertical spindle and reciprocating table

(m)

Horizontal spindle and rotary table

(iv)

Vertical spindle and rotary table.

• The

majority of surface grinders are of the horizontal table type. In the

horizontal type of machine, grinding is normally done by the periphery of the wheel.

• The area

of contact is small, and the speed is uniform over the grinding surface.

• Small

grain wheels can be used, and the finest finishes obtained.

• The

vertical type, surface grinders apply the face or side of the wheel, and cupped

cylindrical, or segmented wheels are used.

• The area

of contact may be large, and stoke can be removed rapidly. But a crisscross

pattern of grinding scratches are left on the work surface.

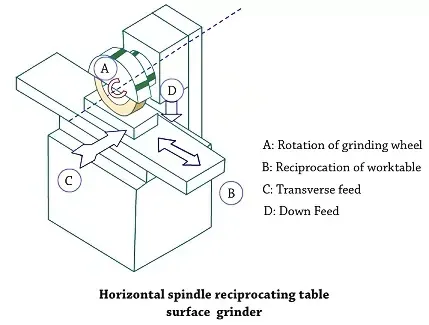

Horizontal spindle reciprocating table surface grinder:

• The block

diagram of a straight wheel horizontal spindle reciprocating table surface

grinder is shown in figure.

• A disc

type grinding wheel performs the grinding action with its peripheral surface.

Both traverse and plunge grinding can be carried out in this machine as shown

in figure.

Base:

• The base

has a column at the back for supporting the wheel head. The base also contains

the drive mechanisms.

Table:

• The table

is fitted to the saddle on carefully machined guide ways. It reciprocates along

ways to provide the longitudinal feed.

• T-slots

are provided in the table surface for clamping workpieces directly on the table

or for clamping grinding fixtures or a magnetic chuck.

• On some

machines, the table can also be moved in or out from the vertical column which

supports the wheelhead. This movement is known as cross- feed.

Wheelhead:

• The

wheelhead is mounted on the column secured to the base.

• It has

ways for the vertical slide which can be raised or lowered with the grinding

wheel only manually by rotating a hand wheel to accommodate workpieces of

different heights and to set the wheel for depth of cut.

•

Horizontal, crosswise movement of the wheel slide with the wheel, actuated by

hand or by hydraulic drive, accomplishes the cross feed of the wheel.

• The

grinding wheel rotates at constant speed - it is powered by a special built -

in motor.

Operation:

• The

workpiece reciprocates under the wheel, and the wheel or the table feeds

axially between passes to produce a fine flat surface.

• Wheel

downfeed determines depth of cut and final height of the piece from the table

to the wheel.

• The amount

of feed must only be equal to a few hundredth of a millimeters.

(i) For

example, steel is rough ground with a depth of cut between 0.02 and 0.05mm and

finish-ground with a depth of cut of 0.005 to 0.01 mm.

(ii) In the

case of grey cast-iron the depth of cut in rough grinding may be anything

between 0.08 and 0.15 mm and in finish grinding between 0.02 and 0.05 mm.

Horizontal spindle rotary table surface grinder:

• Surface

grinding in this machine is shown in figure.

• In

principle, the operation is same as that for facing on the lathe.

• This

machine has a limitation in accommodation of workpiece and therefore does not

have wide spread use.

• The

swiveling the worktable, concave or convex or tapered surface can be produced

on individual part as illustrated in figure.

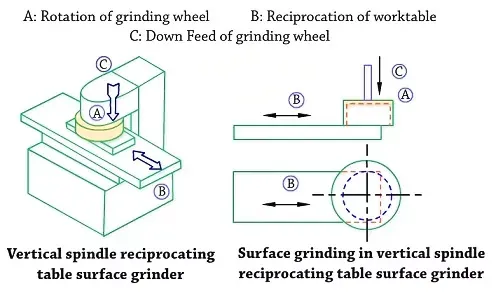

Vertical spindle reciprocating table surface grinder:

• This

grinding machine with all working motions is shown in figure.

• The

grinding operation is similar to that of face milling on a vertical milling

machine.

• In this

machine a cup shaped wheel grinds the workpiece over its full width using end

face of the wheel as shown in figure.

• This

brings more grits in action at the same time and consequently a higher material

removal rate.

Vertical spindle rotary table surface grinder:

• The block

diagram of a vertical spindle rotary table surface grinder is shown in figure.

• The

principal elements of this machine consists of a magnetic chuck which can be

moved under or away from the wheel for unloading and loading the work.

• Slide

which is mounted on horizontal bed ways.

• The

grinding spindle is mounted vertically on the face of a column and rotates in a

fixed position feeding only along its axis.

• The rotary

table travels beneath the wheel as grinding wheel rotates.

• This

combination of table travel and table rotation exposes the entire surface of

the workpiece to the wheel and eliminates the need for any lateral movement of

the wheel.

Tool and cutter grinding machine:

• Tool and

cutter grinders are used mainly to sharpen and recondition multiple tooth

cutters like reamers, milling cutters, drills, taps, hobs and other types of

tools used in the shop.

• With

various attachments they can also do light surface, cylindrical, and internal

grinding to finish such items and jig, fixture, die and gauge details and

sharpen single point tools.

• They are

classified according to the purpose of grinding, into two groups,

(i)

Universal tool and cutter grinders

(ii)

Single-purpose tool and cutter grinders.

Universal tool and grinders:

• Universal

tool and cutter grinders are particularly intended for sharpening of

miscellaneous cutters.

•

Single-purpose grinders are used for grinding tools such as drills, tool-hits,

etc.

• In large production

plants where large amount of grinding work is necessary to keep production

tools inpropercutting condition.

• In

addition, tools can be ground uniformly and with accurate cutting angles.

• A typical

tool and cutter grinder is shown in figure below,

• The

universal tool and cutter grinder has the following principal parts;

Base:

• The saddle

is mounted directly on the top of the base.

• It is

heavy, rugged and box-type.

• It carries

all other parts of the machine.

• It is made

up of heavy cast iron to absorbs impact load and vibrations during cutting

stocks.

Saddle:

• The saddle

is mounted directly on the top of the base.

• It moves

on antifriction ball bearings on hardened ways.

• The column

supporting the wheel head is mounted on the saddle and it can he moved up and

down and swivelled to either side.

• The saddle

also provides the means for moving the work forward and backward.

Table:

• The table

rests and moves on a top base which is mounted over the saddle.

• The top of

the base contains the gears and mechanism which control the table movement.

• The work

table is mounted on the sub-table which has T-slots for mounting the work and

attachments used on the machines.

• The work

table can be swivelled which enables the operator to grind tapers.

Headstock and tailstock:

• The

headstock and tailstock are mounted on either side of the table similar to

those on a cylindrical grinder.

• The

workpiece is positioned between the centres and driven exactly as in a

cylindrical grinder.

Wheel head:

• The wheel

head is mounted on a column on the back of the machine.

Grinding wheel:

• Three

different types of grinding wheels are extensively used in cutter grinding.

They are;

(i) The

"straight" or disc-shaped wheel

(ii) The cup

type in either the straight or flaring form

(m) The dish

type.

Centreless grinding machines:

• This

grinding machine is a production machine in which out side diameter of the

workpiece is ground.

• The

workpiece is not held between centres but by a work support blade.

• It is

rotated by means of a regulating wheel and ground by the grinding wheel.

• The

principal elements of an external centreless grinder are shown, Figure shows

the grinding wheel, regulating or back up wheel, and the work rest. Both wheels

are rotated in the same direction.

• The work

rest is located between the wheels. The work is placed upon the work rest, and

the latter, together with the regulating wheel, is fed forward, forcing the

work against the grinding wheel.

• The axial

movement of the work past the grinding wheel is obtained by tilting the

regulating wheel at a slight angle from horizontal. An angular adjustment of 0

to 8 or 10 degrees is provided in the machine for this purpose.

Through grinding:

• The

regulating wheel revolving at a much lower surface speed than grinding wheel

controls the rotation and longitudinal motion of the workpiece.

• The

regulating wheel is kept slightly inclined to the axis of the grinding wheel

and the workpiece is fed longitudinally as shown in figure.

Infeed grinding:

• Which is

similar to plunge grinding or form grinding.

• The

regulating wheel is drawn back so that workpieces may be placed on the

work-rest blade. Then it is moved in to feed the work ,against the grinding

wheel.

• This

method is useful to grind shoulders, and formed surfaces.

Endfeed grinding:

• Used to

produce taper, either the grinding wheel or regulating wheel or both are formed

to a taper.

• The work

is fed lengthwise between the wheels and is ground as it advances until it

reaches the end stop.

Advantages of centerless grinding:

• As a true

floating condition exists during the grinding process, less metal needs to be

removed.

• The

workpiece being supported throughout its entire length as grinding takes place,

there is no tendency for chatter or deflection of the work and small, fragile or

slender workpieces can be grounded easily.

• The

process is continuous and adapted for production work.

• No centre

holes, no chucking or mounting of the work on mandrels or other holding devices

are required.

• The size

of the work is easily controlled.

• A low

order of skill is needed in the operation of the machine.

Disdvantages of centerless grinding:

• Work

having multiple diameter is not easily handled.

• In hollow

work, there is no certainly that the outside diameter will be concentric with

the inside diameter.

• This

process is not suitable for large size workpiece.

• This

process is useful only for large volume production.

Grinding wheel:

• A grinding

wheel is a rotating abrasive wheel used to ground the workpiece.

• Grinding

wheel is made up of crushed hard particles [abrasives] and embedded in a matrix

called the bond.

• The sharp

edges of the abrasive particles act as acting edge to ground the workpiece.

Abrasives:

• An

abrasive is a substance that is used for grinding and polishing operations.

• It should

be pure and have uniform physical properties of hardness, toughness, and

resistance to fracture to be useful in manufacturing grinding wheels.

• Abrasives

may he classified in two principal groups;

(i) Natural

(ii) Artificial

or manufactured.

Natural:

• The

natural abrasives include sandstone or solid quartz, emery, corundum, and

diamond.

• Sandstone

or solid quartz is one of the natural abrasive stones from which grindstones

are shaped.

• The quartz

cutting agent is relatively shaft that materials harder than quartz cannot be

abraded or ground rapidly.

• Emery is a

natural aluminium oxide.

• It

contains from 55 to 65 percent alumina, the remaining consist of iron oxide and

other impurities.

• Coruntlum

is a natural aluminium oxide, It also contains from 75 to 95 percent aluminium

oxide, the remaining consists of impurities.

• Both emery

and corundum have a greater hardness and better abrasive action than quartz.

• Diamonds

of less than gem quality are crushed to produce abrasive grains for making

grinding wheels to grind cemented carbide tools and make lapping compound.

• As a

result of the impurities in and lack of uniformity of these natural abrasives,

only a very a small percentage of grinding wheels are produced from natural

abrasives.

Artificial:

• Artificial

or manufactured abrasives include chiefly;

(i) Silicon

carbide, and

(ii)

Aluminium oxide.

Silicon Carbide:

• Silicon

Carbide [SiC] abrasive is manufactured from 56 parts of silicon sand, 34 parts

of powdered coke, 2 parts of salt, and 12 parts of saw dust in a long,

rectangular electric furnace of the resistance type that is built up of loose

brickwork.

• Sand

furnishes silicon, coke furnishes carbon, sawdust makes the charge porous, and

salt helps to fuse it.

• The

abrasive wheels are denoted by ‘S’.

• There are

two types of silicon carbide abrasives.

• Green grit

which contains at least 97 percent silicon carbide, and black grit which

contains at least 95 percent ofsilicon carbide.

• This form

is harder but weaker than the latter.

• Silicon

carbide follows the diamond in order of hardness, but it is not as tough as

aluminium oxide.

• It is used

for grinding materials of low tensile strength such as cemented carbides, stone

and ceramic materials, gray cast iron, brass, bronze, copper, aluminium,

vulcanized rubber, etc.

Aluminium

oxide:

• Aluminium

oxides are manufactured by heating minerals of bauxite.

• The

hydrated aluminium oxide clay containing silica, iron oxide, titanium oxide,

etc., mixed with ground coke and iron borings in a arc-type electric furnace.

• Aluminium

oxide is tough and not easily fractured, so it is better adopted to grinding

materials of high tensile strength, such as steels, argon steels, high speed

steels, annealed malleable iron, wrought iron, tough bronzes.

• Grinding

wheels are denoted by letter A.

Bond and bond materials:

• A bond is

an adhesive substance that is employed t0 hold abrasive grains together in the

form of sharpening stones or grinding wheels.

• Commonly

used bond materials for different bonds are,

• These

bonds may be used with either silicon carbide or aluminium oxide.

Vitrified bonding process:

• Vitrified

wheels are made by bonding clay and melted to a glass like consistency with

abrasive grains.

• The clay

and abrasive grains are thoroughly mixed together with sufficient water to make

the mixture uniform.

• The fluid

mixture is then poured into moulds and allowed to dry. When it has dried to a

point where it can be handled, the material is cut trimmed to more perfect size

and shape.

• It is then

heated or burned in a kiln in much the same manner as brick or tile is burnt.

• When the

burning proceeds, the clay vitrifies; that is, it fuse and forms a porcelain,

or glasslike substance that surrounds and connects the abrasive grains.

• The high

temperature employed in this process tends to anneal the abrasives to some

extent.

• Vitrified

bond gives a whee] good strength as well as porosity to allow high stock

removal with cool cutting.

•

Disadvantages of vitrified bonded wheels are their sensitivity to impact and

their low bending strength.

• About 75

per cent of the wheels now manufactured are made with this bond.

• A

vitrified bonded wheel is denoted by the letter V.

Silicate bonding process:

• Silicate

wheels are made by mixing abrasive grains with silicate of soda or water glass.

• The

mixture is packed into moulds and allowed to dry.

• The

moulded shapes are then baked in a furnace at a temperature of 260°C for

several days.

• The

silicate bond releases the abrasive grains more readily than the vitrified

bond, the abrasive grains are not annealed as in the vitrified process, and

silicate wheels are waterproof.

• These

characteristics make silicate wheels valuable for grinding edged tools and

other operations where heat must he held to a minimum with or without the aid

of a coolant.

• A silicate

bonded wheel is denoted by the letter ‘S’.

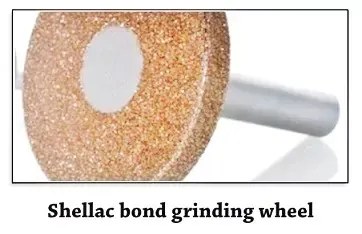

Shellac bonding process:

• Shellac

bonded wheels are also known as elastic bonded wheels.

• In this

process, the abrasive and shellac are mixed in heated containers and then

rolled or pressed in heated moulds.

• Later the

shapes are hacked it few hours at the temperature of approximately 150°C.

• The

elasticity of this bond is greater than in other types and it has considerable

strength.

• It is not

intended for heavy duty.

• Shellac

bond is cool cutting on hardened steel and thin sections, and is used for

finishing chilled iron, cast iron and steel rolls, hardened steel cams and

aluminum pistons, and in very thin sections, for abrasive cutting of machines.

• A shellac

bonded wheel is denoted by the letter 'F'.

|

Resinoid

bonding process:

• Resinoid

wheels are produced by mixing abrasive grains with synthetic resins and other

compounds.

• Then the

mixture is placed in moulds and heated at about 200°C.

• At this

temperature, the resin sets to hold the abrasive grains in whee] form.

• Wheels

bonded with synthetic resin, such as Bakelite and Redmanol, are used for

purposes which require a strong, free high speed wheel.

• They can

remove stock very rapidly.

• They are

useful for precision grinding cams, and rolls requiring high finish.

• A resinoid

bonded wheel is denoted by the letter B.

Rubber bonding process:

• Rubber

bonded wheels are prepared by mixing abrasive grains with pure rubber and

sulphur.

• Then the

mixture is rolled into sheets, and wheels are punched out of the sheets on a

punch press.

• Following

that, the wheels are vulcanized.

• Rubber

bonded wheels are more resilient, less heat resistant, and more dense than

resinoid bonded wheels.

• They are

used where good finish is primary require.

• They are

strong and tough enough to make extremely thin wheels.

• A rubber

bonded wheel is denoted by the letter R.

Oxy-chloride bonding process:

• This

process consists of mixing abrasive grains with oxide and chloride of

magnesium. The mixing of bond and abrasive is performed in the same way as for

vitrified bonded wheel.

•

Oxy-chloride bonds are employed in making wheels and wheels segments for use in

disc-grinding operations.

•

Oxy-chloride bonds are employed in making wheels and wheels segments for use in

disc-grinding operations.

• The bond

ensures a cool cutting action.

• So

grinding is best done dry.

• An

oxy-chloride bonded wheel is denoted by the letter 'O'.

Grits:

• The grain

or grit number indicates in a general way the size of the abrasive grains used

in making a wheel, or the size of the cutting teeth, since grinding is a true

cutting operation.

• Grain size

is denoted by a number indicating the number of meshes per linear inch [25.4

mm] of the screen through which the grains pass when they are graded after

crushing.

• The

following list shows the of grain ranging from very coarse to very fine, it

includes all the ordinary grain sizes commonly used in the manufacture of

grinding wheels:

• In case

grinding wheels are manufactured from special grain combinations, the grinding

wheel manufacturer may use an additional symbol appended to the standard grain

size number.

Example:

(i) 36 -

Normal standard.

(ii) 36.5 -

Special grain combination.

• The size

of abrasive grain required in a grinding wheel depends on the amount of

material to he removed, the finish desired, and the hardness of the material

being ground.

• In

general, coarse wheels are used for fast removal of materials.

• Fine

grained wheels are used for soft, ductile materials but generally a fine grain

should he used to grind hard, brittle materials.

Grade:

• The term

'grade' as applied to a grinding wheel refers to the tenacity or hardness with

which the bond holds the cutting points or abrasive grains in a place.

• It dose

not refer to the hardness of the abrasive grain.

• The grade

shall be indicated in all bonds and process by a letter of the English

alphabet, A denoting the softest and Z the hardest grade.

• The term

'soft' or 'hard' refer to the resistance of a bond offers to disruption of the

abrasives.

• A wheel

from which the abrasive grains can easily be dislodged is called soft, whereas

one which holds the grains more securely is called hard.

• The grades

are denoted as shown in table below:

• The grade

of the grinding wheel depends on the hardness of the material being ground, the

arc of the contact, the wheel and work speeds, and the condition of the

grinding machine.

• Hard

wheels are recommended for soft materials and soft wheels for hard materials.

Structure:

• Abrasive

grains arc not packed in the wheel but are distributed through the bond.

• The

relative spacing is referred to as the structure and denoted by the number of

cutting edges per unit area of wheel face as well as by number and size of void

spaces between grains.

• The

primary purpose of structure is to provide chip clearance and it may be open or

dense.

• The

structure commonly used is denoted by numbers as shown in table:

• The

structure of a grinding wheel depends on the hardness of the material being

ground, the finish required, and the nature of the grinding operation.

• Soft,

tough and ductile materials and heavy cuts require an open structure, whereas

hard and brittle materials and finishing cuts require a dense structure.

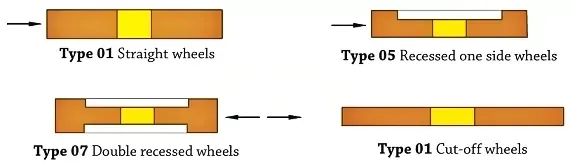

Wheel shapes and factors for wheel selection:

• Grinding

wheels are made in many different shapes and sizes to adapt them for use in

different types of grinding machines and on different classes of work.

• They fall

into the following broad groups;

(i)

Straight-side grinding wheels

(ii)

Cylinder wheels

(m) Cup

wheels

(iv) Dish

wheels.

• The shapes

of grinding wheels have been standardized so that those commonly use in

production and tool room grinding may be designated by a number or name or

both.

• The sizes

of wheels may be referred to a system of key letters so that their dimensional

specifications may be written easily.

Straight wheels:

• No. 1, 5,

and 7 are the kind generally used for cylindrical, centreless, and surface

grinding operations. Wheels of this form vary greatly in size.

• The

diameter and width of face naturally depending upon the class of work for which

the wheel is used and the size and power of the grinding machine.

Tapered face straight wheel:

• No. 4 is

primarily used for grinding thread, gear teeth, etc.

Cylinder or wheel ring:

• No. 2 is

used for producing flat surfaces, the grinding being done with the end face of

the wheel.

Cup wheel:

• No. 6 is

used for grinding flat surfaces by traversing the work past the end or face of

the wheel. Flaring cup whee] No.11 is used for grinding in tool room.

Dish wheel:

• No. 12 is

also used for tool room work. The thinness of the wheel permits it grind the

surface at narrow places. Saucer wheel No. 13 is generally used for sharpening

of circular or band saws. The principal dimensions of a grinding wheel are the

outside diameter, bore diameter, and the width.

Segmented wheels:

• Segmented

wheels are used chiefly on vertical spindle, rotary, and reciprocating- table

surface grinders and way grinders.

• Grinding

wheels of the straight wheel type can be supplied with a large variety of face:

flat, pointed, concave, convex, etc. These faces are used for grinding special

contours and sharpening saws.

Selection of grinding wheels:

• It is

customary for grinding wheel manufacturers to provide, through their published

literature, information on the selection and use of grinding wheels, but it may

not always be possible or convenient for users to take advantage of such

consultative service.

• The need

for ready to use general guide on grinding wheels has been keenly felt and the

Indian Standard (IS: 1249-1958] gives recommendations on the general

considerations which should guide the selection of grinding wheels for

different applications.

• In

selecting a grinding wheel there are four constant factors and four variables;

• Constant

factors:

(i) Material

to be ground

(ii) Amount

of stock to be removed

(iii) Area

of contact.

(iv) Type of

grinding machine

• Variable

factors:

(i) Wheel

speed

(ii) Work

speed

(iii) Condition

of the machine

(iv)Personal

factor

The material to be ground:

(i) Aluminium

Oxide abrasive is recommended for materials of high tensile strength and

silicon carbide for low tensile strength.

(ii) Fine

grain is used for hard and brittle materials and coarse grain for soft ductile

metals.

(iii) Hard

wheel is used for soft materials and soft wheel for hard materials.

(iv) Generally,

close spacing is required for hard and brittle materials and wide for soft and

ductile.

(v) The

class of work usually dictates the bond to be used. Bond selection, of course,

can be safely left to the manufacturers, if the class of work for which the

wheel is required is clearly stated. However, majority of wheels are

manufactured with vitrified bonds.

• Amount of

stock to be removed:

(i) This

involves accuracy and finish.

(ii) Coarse

grain is used for fast cutting and fine grain for fine finish

(iii) Wide

spacing for rapid removal and close for fine finish.

• Resinoid,

rubber, and shellac bond for high finish.

Maintenance of grinding wheel:

• To improve

the cutting capacity.

• To improve

the efficiency of grinding wheel.

• To run the

grinding wheel in concentric speed with spindle.

• The

grinding wheel can be maintained in following ways;

(i) Dressing

(ii) Truing

(iii)

Balancing.

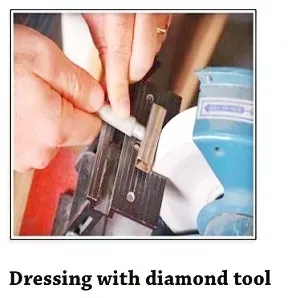

Dressing:

• Dressing

removes loading and breaks away the glazed surface, so that sharp abrasive

particles are again presented to the work.

• This is

done with various type of dressers.

• A common

type of wheel dresser, known as the star-dresser, is shown below.

•

Star-dresser consists of a number of a hardened steel wheels with points on

their periphery.

• The

dresser is held against the face of the revolving wheel and moved across the

face to dress the hole surface.

• This type

of dresser is used to dress coarse-grain abrasive wheels used for rough

snagging work.

• Another

type of wheel dresser consists of a steel tube filled with a bonded abrasive.

• The end of

the tube is held against the wheel and moved across the face.

• The grade

of abrasive in the dresser may vary for different types of dressing operations.

• Abrasive

wheel dressers operates at high speed are frequently used to dress other

wheels.

• They are

used to dress wheels where a fair degree of finish is desired on the work.

• For

precision and high finish grinding, small industrial diamonds, known in the

trade as bort, are used.

• The

diamond or group of diamonds is mounted in a holder. The diamond should be kept

pointed, since only the point can be used for cutting.

• This is

done by the holder down at a 15° angle and using a new surface each time the

wheel is dressed.

• A good

supply of coolant should he used when dressing with a diamond, as overheating

can causes the diamond to fracture or drop out of its setting.

• Very light

cuts only may be taken with diamond tools.

• This

dressing process may use following dressing tools;

(i) Cluster

type tool: Used for roughing and commercial finishes.

(ii)

Corrugated disc dressers: Made of special alloy steel, used for superior

finish.

(iii) Disc

dressers: Steel disc with teeth used for medium grade roughing wheels and for

cam and crank shaft grinding wheels.

Truing:

• Truing is

the process of changing the shape of the grinding wheel as it becomes worn from

an original shape, owing to break away from the abrasive and bond.

• This is

done to make the wheel true and concentric with the bore, or to change the face

contour for form grinding.

• Truing and

dressing are done with the same tools, but not for the same purpose.

• The only

satisfactory method of truing a wheel is by the use of a diamond tool in a

similar manner as explained before.

• In turning

a wheel with a diamond, the feed rate must not exceed 0.02 mm, otherwise

grooves may be cut into the wheel.

• More

popular is form-truing with a crushing roll. In this, a roll, shaped to the

desired profile, is forced against the revolving wheel, crushing the

corresponding shape into it.

• Rolls may

be of two types: Idler in which the wheel drives the roll; and Power driven, in

which a small motor drives the roll which, in turn, rotates the wheel by

frictional contact.

• Wheels

trued by crushing cut faster and run cooler than those trued with a diamond.

• Crushing

produces a wheel with many sharp pointed grains, while diamond truing tends to

produce many grains with flat surfaces.

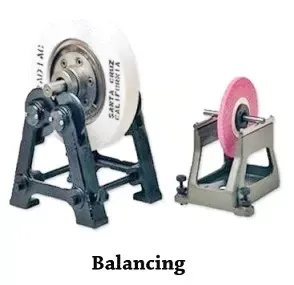

Balancing:

• If wheels

become out of balance through wear and cannot be balanced by truing or

dressing, they should be removed from the machine and discarded.

• Wheels

should be tested for balance occasionally and rebalanced if necessary.

• Wheels

that are out of balance not only produce poor work but may put under strains on

the machine.

• Small

wheels may be balanced by milling a short recess on the inside of the flanges

and filling with lead.

• Large

wheels should he placed on a balancing stand and balanced by moving weights

around a recessed flange.

•

Now-a-days, grinding wheel mounts are provided with devices to enable balancing

to be done whilst the wheel is running and between grinding operations.

0 Comments