Wire Cut EDM, Principle of Wire Cut EDM, Applications of Wire Cut EDM, Advantages of Wire Cut EDM, Disadvantages of Wire Cut EDM

Principle of Wire Cut EDM:

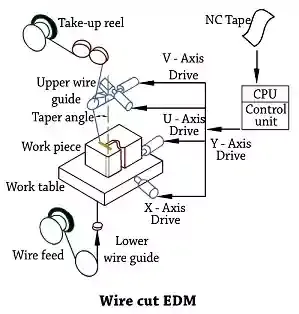

The basic mechanism of metal removal in wire cut EDM is

identical to that in Die-Sinking type EDM. Instead of a moving electrode, the

electrode in this process is a moving wire of Cu or Brass.

A vertically oriented wire is fed into the workpiece

continuously travelling from a supply spool to a take up spool. For this

purpose, a hole is pre-drilled in the workpiece, through which the wire

electrode will pass. The whole workpiece is not submerged in dielectric medium.

The working zone alone is supplied with a co-axial jet of dielectric medium. This

system removes the eroded particles efficiently and keep the working zone cool.

One of the most important aspects in Wire cut EDM is its ability to cut complex

two dimensional profiles. The machine table on which the workpiece is held, has

movements along x-axis and y-axis. The drive unit for the machine table are

controlled by the numerical control units based on CNC system. This system is

easily programmable for linear and circular path interpolation. They provide

high resolution data for accurate control of the slides of the worktable. This

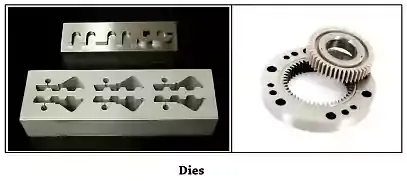

makes this method capable of machining any complicated through hole dies of

electrically conductive materials.

Applications, Advantages & Disadvantages of Wire Cut EDM

Applications of Wire Cut EDM:

• Widely used in making of Press tool Dies.

• Re-sharpening of cutting tools and broaches.

Advantages of Wire Cut EDM:

• Tool manufacturing and storage of tools not required.

• Heat treatment distortions are totally avoided.

• Cycle time for die manufacture is shorter.

• Inspection time is reduced, due to single piece

construction of dies with high positioning accuracy.

• Avoids rejections, due to initial planning and checking

the program.

Disadvantages of Wire Cut EDM:

• Initial setup cost is too high.

• The wire cost is too high.

• If any wire break, total setup need to repeat again.

END

0 Comments