Needs of NC System, Features of NC System, Advantages of NC systems, Limitations of NC systems & Suitability of NC systems (CNC)

Need of NC machines:

• Need of high accuracy in manufacturing complicated parts.

• To manufacture complex shaped components.

• To reduce the machining time on conventional machine operator has to stop the machine frequently and measure the past dimensions in order to ensure that did not overcut the material.

Features of NC system:

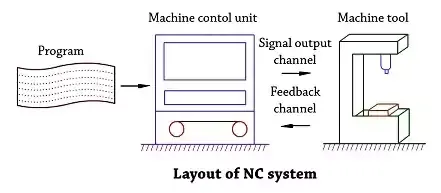

• A NC system consists of three basic component,

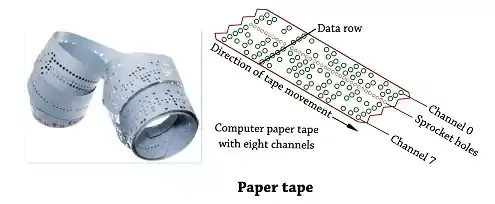

• Program of instructions [punched tape]

• Machine control unit [MCU]

Program of instructions (Punched tape):

• This serves as input to CPU.

• It is in the form of punched tape/card.

• It is a detailed step by step set of directions which instruct the machine tool what to do.

• These instructions are called as part program.

• The part program is written in the form of blocks, where each block contains the data required for one complete action of machine tool.

• Program written using numerical and symbols which can be interpreted by the control unit.

Machine control unit (MCU):

MCU consists of two main parts,

(i) Data Processing Unit [DPU]

(ii) Control Logic Unit [CLU]

Data Processing Unit [DPU]

• It consists of punched tape reader, decoders, data buffer and power source.

• The punched tape reader is a electromechanical device used to run/read the tape and stored the punched data in data buffer.

• Decoders is used to decode the information received from tape reader and fed to control loop unit to control the various motions of machine tool.

• Data buffer stores the data temporarily in form of a block.

• Power source - to supply power. ‘

• Decoders is used to decode the information received from tape reader and fed to control loop unit to control the various motions of machine tool.

• Data buffer stores the data temporarily in form of a block.

• Power source - to supply power.

Control logic unit [CLU]

• It control the action of machine tool and DPU.

• It sends the signal to driving devices of machine tool once the previous block operation is completed.

• Same time it also instruct the DPU to read the next block.

• CLU also receives the feedback signal.

• It also control the auxiliary function such as coolant on / off, spindle on /off, spindle direction, speed change and etc.

Machine tool:

• In NC machine tool unlike conventional machine tool, each axis of motion is equipped with a separate driving device which replaces the hand wheel of conventional machine.

• The driving device may be a DC motor, hydraulic motor, stepping motor or servo motor.

• These separate driving devices are used for controlling the tool direction in X, Y and Z axis.

Feedback device:

• NC machine tools are equipped with feedback devices to ensure that tool/work table is moved to desired position as per the instructions of MCU.

• Feedback device sensor senses the actual movement of work table/ tool and sends back the data to control unit.

• The control unit compares the date received from feedback device with actual data to machine tool.

• If both values are not same control unit will instruct the machine tool to move again by difference amount.

• If both values are same [or difference is zero], next block of instruction will be operated.

Advantages of NC systems:

• Reduced non-productive time

• Reduced fixturing

• Reduced manufacturing lead times

• Greater manufacturing flexibility

• Improved quality control

• Reduced inventory

• Reduced inspection requirements

• Less wastage and scrap

• Even semi-skilled operator can run the machine

• One operator can control more than one machine.

Limitations of NC systems:

• Higher initial investment cost

• Higher running costs and maintenance cost

• Finding trained manpower could be a challenge

• Breakdowns can be expensive

• Elaborate accessories like programming and tape

• Punch /reader systems adds to be cost

• Complicated maintenance.

Suitability of NC systems:

Typically NC machines are most suitable for a batch type manufacturing especially when

• Parts are processed frequently and in small lots.

• The part geometry is complex.

• Machining involves variety of operations.

• Changes in engineering design can be made easily.

• Close tolerances are to be held.

Find the next topic CNC

0 Comments