Press Working, Press Selection, Press Operations (Cutting, Bending, Drawing, Deep Drawing, Punching, Blanking, Notching, Lancing, Piercing, Coining & Embossing), Die set components, Clearances

Press working:

Press working is a chipless production process in which

components are produced from sheet metal. This process is also termed as cold stamping. Press working

operations are usually done at room temperature. It is most widely used for a

good surface finish and obtaining an exact and accurate shape with very low

cost as compared to many other operations like casting forging. Press working

is used to make file cabinets, almirahs, car bodies, beverage can, kitchen

utensils, hopper, pipes, cannisters etc. This process entails the following

advantages:

• The weight of fabricated part is small.

• Items of diversified shapes, both simple and complex, such

as washers, bushings, retainers of ball bearings etc can be made easily.

• The parts made by cold sheet metal working have narrow

tolerances with a high surface finish.

• The productivity of labour is quite high.

Types of presses:

The machine used for press working is called a press. It consists of a frame which supports a ram, a bed and a source or mechanism for operating the ram. The presses can be classified according to various characteristics.• Source of power

» Mechanical presses

» Power presses

• Type of frame

» Open frame presses

» Closed frame presses

• According to action

» Single action

» Double action

» Triple action

• Mechanism used for applying power to ram

» Crank

» Eccentric

» Cam

» Toggle

» Knuckle

» Rack and pinion

» Hydraulic

• Number of drive gears

» Single drive

» Twin drive

» Quadruple drive.

Press selection:

The presses can be classified according to various

characteristics. The factors which should be considered while selecting a press

for a given job are;

• The overall work size

• The stock thickness and material

• Kind of operation to be performed

• Power required

• Speed of operation.

Press Operations:

The sheet metal operations done on a press may be grouped

into two categories;

• Cutting operations

• Forming operations.

In cutting operations, the work piece is stressed beyond its

ultimate strength. The stresses caused in the metal by the applied forces will

be shearing stresses The cutting operations include:

• Blanking

• Punching

• Notching

• Perforating

• Trimming

• Shaving

• Slitting

• Lancing etc.

In forming operations, the stresses are below the ultimate

strength of the metal. In this operation, there is no cutting of the metal but

only the contour of the work piece is changed to get desired product. The

forming operations include:

• Bending

• Drawing

• Redrawing

• Squeezing.

Cutting Off:

Cutting off is the process of shearing the sheet metal by

using two sharp cutting edges. This operation is performed to cut large size

sheet metal into number of small pieces. Basically this operation performed by

hand tool such as cutter, chisel etc.

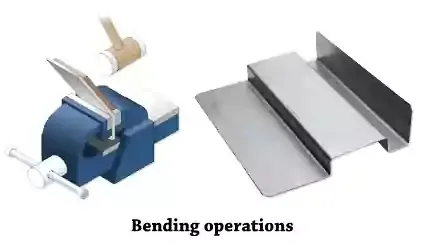

Bending:

In bending all sheet material are stressed beyond the

elastic limit in tension on the outside and in compression on the inside of the

bend. Stretching of the sheet metal on the outside makes the stock thinner.

Bending is sometimes called as forming, which involves angle bending, roll

bending, roll forming, seaming and spinning.

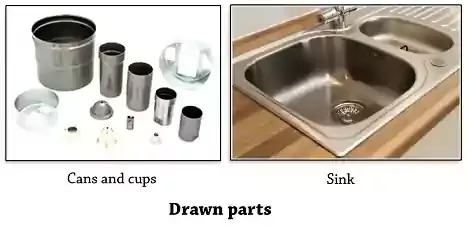

Drawing:

Process of forming a flat piece [blank] in to a cup

shape. The blank is placed over a die cavity and held down flat against the

blank holder. The punch pushes the blank into the cavity, thus forming a cup

shape. The depth of draw may be shallow, moderate or deep. If the depth of the

formed cup is equal to or greater than its diameter, the process

is shallow drawing, it is termed as deep drawing. Beverage cans,

sinks, automobile body panels, etc are produced.

Punching:

Punching is the operation of producing circular holes on a

sheet meta] by a punch and die. The material punched out is removed as waste.

Blanking:

Blanking is similar to punching expect the slug is saved as

the finished product. Simply, the metal around the part is removed.

Notching:

Notching produces a partial hole in the edge of the sheet,

strip or blank. Cutting on one side generates lateral deflection of the punch.

Heel is provided to the punch with little or no clearance opposite the cutting

edge A notch can be made in any shape. The purpose of notching is generally to

release metal for fitting up.

Lancing:

The metal is sliced or slit to free up metal without

separating it from the original sheet. No metal is removed, therefore no slug.

This process can save material and eliminate the need for expensive scrap

removal systems.

Piercing:

Process of making a hole in the metal without removing a

slug. The meta] is pushed back to form a ragged edge on the back side of the

hole A pierced hole looks somewhat like a bullet hole in a sheet metal.

Coining:

Coining is a squeezing process that uses a great deal of

force to plastically deform of workpiece to induce plastic flow on the die

cavity. Coining is used to produce coins, medals, badges, buttons,

precision-energy springs and precision parts with small or polished surface

features. This reduces surface grain size, and improve surface hardens. Coining

typically requires higher tonnage presses than squeezing, because the workpiece

is plastically deformed.

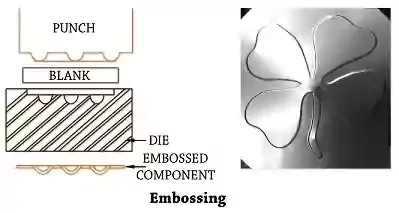

Embossing:

The metal thickness is not changed during this process. The

design shows on both sides. Depressed details on one side. Relief details on

other side. The metal thickness is not changed during this process. Used to

produce letters or fancy designs on thin sheets.

Die set components (Press working terminology):

A simple cutting die used for punching and blanking

operations is shown in figure below. The definitions of the main components of

the die and press are also given below.

• Bed:

The bed is the lower part of a press frame that serves as a

table to which a bolster plate is mounted.

• Bolster Plate:

This is a thick plate secured to the press bed, which is

used for locating and supporting the die assembly. It is usually 5 to 12.5 cm

thick.

• Die Set:

It is unit assembly which incorporates a lower and upper

shoe, two or more guideposts and guidepost bushings.

• Die:

The die may be defined as the female part of a complete too]

for producing work in a press. It is also referred to a complete tool

consisting of a pair of mating members for producing work in a press.

• Die Block:

It is a block or a plate which contains a die cavity.

• Lower Shoe:

The lower shoe of a die set is generally mounted on the

bolster plate of a press. The die block is mounted on the lower shoe. Also, the

guide posts are mounted in it. It is also called as die-holder.

• Punch:

This is the male component of the die assembly, which is

directly or indirectly moved by and fastened to the press ram or slide.

• Upper shoe:

This is the upper part of the die set which contains

guidepost bushings. It is also called as punch holder because the punch is

mounted on it.

• Punch Plate:

The punch plate or punch retainer fits closely over the body

of the punch and holds it in proper relative position.

• Back up Plate:

Back up plate or pressure plate is placed so that the

intensity of pressure does not become excessive on punch holder. The plate

distributes the pressure over a wide area and the intensity of pressure on the

punch holder is reduced to avoid crushing.

• Stripper:

It is a plate which is used to strip the metal strip from a

cutting or non-cutting punch or die. It may also guide the sheet.

• Knockout:

It is a mechanism, usually connected to and operated by the

press ram, for freeing a work piece from a die.

• Pitman:

It is a connecting rod which is used to transmit motion from

the main drive shaft to the press slide.

• Shut height:

It is the distance from top of the bed to the bottom of the

slide, with its stroke down and adjustment up.

• Stroke:

The stroke of a press is the distance of ram movement from

its up position to its down position. It is equal to twice the crankshaft throw

or eccentricity of the eccentric drives but is variable on the hydraulic press.

Clearances:

While designing a die, the factor that does needs most

consideration is the size of the punch and the opening of the die. The die

opening must be sufficiently larger than the punch to allow a clear fracture of

metals. The difference in sizes of the die opening and punch is known as

clearance. The various methods used for applying clearance are as follows;

• When an accurate hole is required in the sheet metal and

slug is to be discarded, the punch is made to the size of the hole.

• The size of a die opening is obtained by adding the

clearance to the punch size.

• Where the slug or blank accuracy is required, the die

opening size equals the blank size.

• The punch size is obtained by subtracting the clearance

from the die opening size.

• This system of clearance is used in blanking dies.

• The clearance of a component depends upon many factors,

like the thickness and temper of the material.

• In general, harder materials require larger clearances per

side of the die.

• Aluminium is the exception.

• If ‘C’ is the clearance per side of the die opening and

‘t’ the stock thickness, usual clearance per side of the die are given as

follows;

Brass and annealed steel: C = 5.0% of t.

Normalized and hardened steel: C = 56-7% of t.

Aluminium and its alloys: C = 10% of t.

Effect of Clearance:

• Manufacturers have performed many studies on the effect of

clearance on punching and blanking.

• Clearance affects not only the smoothness of the fracture,

but also the deformation force and deformation work.

• A tighter blanking and punching clearance generates more

heat on the cutting edge and the bulging area tightens around the punch.

• These effects produce a faster breakdown of the cutting

edge.

• If the clearance increases, the bulging area disappears

and the roll-over surface is stretched and will retract after the slug breaks

free.

• Less heat is generated with increases in the blanking and

punching clearance, and the edge breakdown rate is reduced.

• The deformation force is greatest when the punch diameter

is small compared to the thickness of the work material.

• In one test, for example, a punching force of about 142 kN

was required to punch 19 mm holes into 8 mm mild steel when the clearance was

about 10 percent.

• With a clearance of about 4.5 per cent, the punching force

increased to 147 kN and a clearance of 2.75 per cent resulted in a force of

153.5 kN.

0 Comments