Introduction to Machine Design

FATIGUE:

When a material is subjected to repeated stresses, it fails at stresses below the yield point stresses. Such type of failure of a material is known as *fatigue. The failure is caused by means of a progressive crack formation which are usually fine and of microscopic size. This property is considered in designing shafts, connecting rods, springs, gears, etc.

ENDURANCE LIMIT:

The endurance limit, also known as the fatigue limit, is a concept used in materials science and engineering to describe the maximum cyclic stress amplitude that a material can endure for an indefinite number of cycles without failure. In simpler terms, it represents the maximum stress level that a material can withstand without developing fatigue failure, even under repeated loading and unloading.

CREEP:

When a part is subjected to a constant stress at high temperature for a long period of time, it will undergo a slow and permanent deformation called creep. This property is considered in designing internal combustion engines, boilers and turbines.

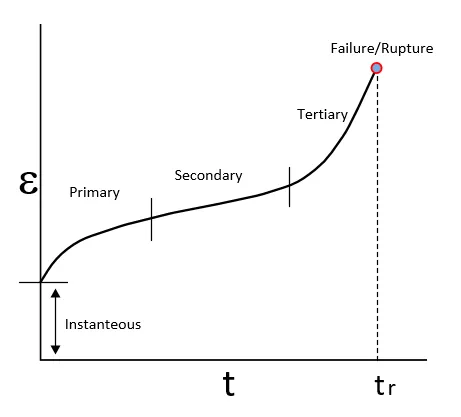

CREEP CURVE:

A creep curve shows how a material deforms over time when subjected to constant stress at high temperatures. It typically has three stages:

- Primary Creep: Initially, deformation rate decreases.

- Secondary Creep: A relatively constant deformation rate.

- Tertiary Creep: Rapid increase in deformation leading to failure.

Each stage depends on factors like temperature and stress. Creep curves are crucial for understanding material behavior in high-temperature applications.

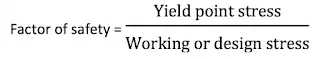

FACTOR OF SAFETY:

It is defined, in general, as the ratio of the maximum stress to the working stress. Mathematically,

In case of ductile materials e.g. mild steel, where the yield point is clearly defined, the factor of safety is based upon the yield point stress. In such cases,

In case of brittle materials e.g. cast iron, the yield point is not well defined as for ductile materials. Therefore, the factor of safety for brittle materials is based on ultimate stress.

This relation may also be used for ductile materials.

STRESS CONCENTRATION:

Stress concentration is when stress increases in certain spots like notches or holes in a material. It can cause early failure, especially under repeated stress.

CAUSES OF STRESS CONCENTRATION:

Stress concentration occurs due to geometric features like notches, holes, or sharp corners in a material. These features disrupt the uniform distribution of stress, causing it to localize at specific points. Other factors contributing to stress concentration include material defects, surface roughness, and changes in cross-sectional area.

REMIDIES OF CAUSES OF STRESS CONCENTRATION:

Design Modification: Redesigning components to eliminate sharp corners, notches, or abrupt changes in geometry can distribute stress more evenly.

Fillets and Radii: Adding fillets or rounded edges to critical areas reduces stress concentration by smoothing out transitions between different surfaces.

Material Selection: Choosing materials with higher toughness and ductility can help mitigate stress concentration effects.

Surface Treatment: Techniques like shot peening or surface coating can improve surface integrity and reduce stress concentration.

0 Comments